Monday, April 18, 2011

U6b Progress Report

As the following photo's illustrate both models are actually being worked on and actually making progress. The most obvious change is the primer, a very light coat of rattle can automotive stuff which worked very well. I cleaned the car bodies with alcohol via cotton swabs and then had to go over everything with tweezers to pick off the "hairs". The paint serves to "blend" everything together and brings out the details like the nbw's on the roof castings. It also brings out the goofs. Not too many, thank you very much, but at least I know where to go to "fix" them.

I got a lot of work done on the underframes, mounting the fuel tanks, battery boxes and jack pads as well as some minor adjustments to the truck mounts. I was originally going to solder up the steps but the thought of making eight of them sounded boring and when that happens I tend to procrastinate. So I made a rubber mold and cast a bunch of them out of high strength resin. While it worked, they were very flexible and fragile and I had to "repair" almost all of them before they were usable. In the end I decided not to use them because they just didn't look right. Back to soldering 6 more sets out of brass.......

The end beams need more work including coupler lift bars (3) and grab irons. The rest of the grab irons will be done using parts out of Presicion Scales bin. Speaking of whom I have a new order going out to those folks soon covering such items as the bells, cab arm rests, air tanks etc. etc.

Some small detail parts have been completed but not installed because painting and weathering has to be completed first. Things like the cab window shades, these are canvas units on metal frames, made from brass wire and tissue already painted and weathered. You can see the mount holes in one of the photo's.

I have found a source for motors that looks good on the surface. These are "surplus" high quality motors that are very inexpensive and at these prices I can afford to give them a try. I'll let you know how this works out.

While it seems like this project is coming to an end I know better. There is a lot of work yet to do. Head down and forge ahead.

Originally one of the goals of this exercise was to build a fairly inexpensive model of an unavailable prototype. I have been having second thoughts about the cost involved. Basing the whole thing on the Athearn drive system was the best decision I've made so far. Even at that power trucks for both units have cost about $70 including the worm gears and caps. Detail parts have cost over $100 so far and more are to come. The basic scratch building materials ran about $30 but I have enough left to build another unit. I still have to purchase a decoder and sound system for both engines. This is not cheap!! Considering I bought a Bachmann Shay at Ebay for about $75 delivered, the economics are a little confused. However, I really enjoy scratchbuilding and there are no models like these available, period. Furthermore, I intend to do this again, I have projects lined up down the road when these are completed.

Truthfully there are mistakes in both of these models. They are far from perfect but then I haven't done this in over 30 years. I have had to relearn a lot of stuff. I have no intention of entering them in any contest and it is unlikely they would win anything if I did. I have never had much use for model contests. Believe me, I know where the problems are with them, I don't need someone else to point them out. I am a much harsher critic than any contest judge could be.

I got a lot of work done on the underframes, mounting the fuel tanks, battery boxes and jack pads as well as some minor adjustments to the truck mounts. I was originally going to solder up the steps but the thought of making eight of them sounded boring and when that happens I tend to procrastinate. So I made a rubber mold and cast a bunch of them out of high strength resin. While it worked, they were very flexible and fragile and I had to "repair" almost all of them before they were usable. In the end I decided not to use them because they just didn't look right. Back to soldering 6 more sets out of brass.......

The end beams need more work including coupler lift bars (3) and grab irons. The rest of the grab irons will be done using parts out of Presicion Scales bin. Speaking of whom I have a new order going out to those folks soon covering such items as the bells, cab arm rests, air tanks etc. etc.

Some small detail parts have been completed but not installed because painting and weathering has to be completed first. Things like the cab window shades, these are canvas units on metal frames, made from brass wire and tissue already painted and weathered. You can see the mount holes in one of the photo's.

I have found a source for motors that looks good on the surface. These are "surplus" high quality motors that are very inexpensive and at these prices I can afford to give them a try. I'll let you know how this works out.

While it seems like this project is coming to an end I know better. There is a lot of work yet to do. Head down and forge ahead.

Originally one of the goals of this exercise was to build a fairly inexpensive model of an unavailable prototype. I have been having second thoughts about the cost involved. Basing the whole thing on the Athearn drive system was the best decision I've made so far. Even at that power trucks for both units have cost about $70 including the worm gears and caps. Detail parts have cost over $100 so far and more are to come. The basic scratch building materials ran about $30 but I have enough left to build another unit. I still have to purchase a decoder and sound system for both engines. This is not cheap!! Considering I bought a Bachmann Shay at Ebay for about $75 delivered, the economics are a little confused. However, I really enjoy scratchbuilding and there are no models like these available, period. Furthermore, I intend to do this again, I have projects lined up down the road when these are completed.

Truthfully there are mistakes in both of these models. They are far from perfect but then I haven't done this in over 30 years. I have had to relearn a lot of stuff. I have no intention of entering them in any contest and it is unlikely they would win anything if I did. I have never had much use for model contests. Believe me, I know where the problems are with them, I don't need someone else to point them out. I am a much harsher critic than any contest judge could be.

Sunday, February 20, 2011

These photo's show the progress I'm making on the U6's. The car bodies are assembled and some detail has been added. NBW etc. The black lines showing on the underframe are Archer weld beads. They look great and I intend to add some more. The overhead shot of the underframe is intended to show the Athearn truck retainer clips which work perfectly.....by accident !

The side view of the underframe shows the truck side frames mounted via some brass channel stock. They are missing the equalizers, springs and spring plates and the sand piping. The equalizers did not turn out very well ( my poor engineering) and I am still mulling over how to proceed. I need 8 identical pieces so they need to be etched, molded or some such to avoid really needless repitition by hand making each one that would never turn out the same.

The hood ends are resin moldings like the roof and truck side frames and I have fitted a brass door to the end showing. This is an access door for the radiator and cooling fan room. That still needs hinges and handles as do all the engine hood doors. I have made an order to Precision Scale for many small detail parts including those items plus horns, brake wheels and housings, sand filler hatches, headlights and more. Both units should start to look "busy" pretty soon. I've decided on brass angle for the handrail stanchions much like Alco switch engines. Fairly easy to fabricate and detail and very strong.

The "cab" unit is going to have interior detail. It is much too open not to. Brake stand, heater, control stand seats etc. painted that weird off green every engine I ever got on was (except the momentary chocolate brown period the SP went through in the late '70's)

The all together shot gives an idea of the "chunkiness" look of typical U6's. There is also an electrical conduit that fits just under the running boards that I intend to include that will visually add to that look.

The end steps are being molded along with m/u drop steps and should be installed at the next update.

The side view of the underframe shows the truck side frames mounted via some brass channel stock. They are missing the equalizers, springs and spring plates and the sand piping. The equalizers did not turn out very well ( my poor engineering) and I am still mulling over how to proceed. I need 8 identical pieces so they need to be etched, molded or some such to avoid really needless repitition by hand making each one that would never turn out the same.

The hood ends are resin moldings like the roof and truck side frames and I have fitted a brass door to the end showing. This is an access door for the radiator and cooling fan room. That still needs hinges and handles as do all the engine hood doors. I have made an order to Precision Scale for many small detail parts including those items plus horns, brake wheels and housings, sand filler hatches, headlights and more. Both units should start to look "busy" pretty soon. I've decided on brass angle for the handrail stanchions much like Alco switch engines. Fairly easy to fabricate and detail and very strong.

The "cab" unit is going to have interior detail. It is much too open not to. Brake stand, heater, control stand seats etc. painted that weird off green every engine I ever got on was (except the momentary chocolate brown period the SP went through in the late '70's)

The all together shot gives an idea of the "chunkiness" look of typical U6's. There is also an electrical conduit that fits just under the running boards that I intend to include that will visually add to that look.

The end steps are being molded along with m/u drop steps and should be installed at the next update.

Wednesday, November 24, 2010

Layout Progress

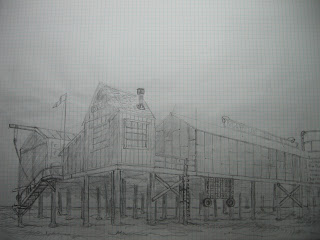

While this image is not very good it will serve as a general view of the overall layout design. The drawing has been erased more times than I care to remember and is still in the process of change. If you have been following this blog you will recognize that the left side of the sketch has already been modified ! At least you all have an overall view of the extent of the whole layout.

I overcame a major obstacle last week by the removal

of a 275 gallon fuel tank that was within the boudaries of the harbor scene on the right side.

It took the new owner of the tank and me several hours of hard labor to get it out of the basement but it is finally done. I immediately began putting down the sills for the new walls in that section that divides off the water heater and the ancient oil heater.

This is the engine service area around Bridge, Oregon. The scene will consist of mountain sloping upwards toward the backdrop covered with pines and spruce etc. the track and structures in the foreground. I am experimenting with the valance. The wavy cut is to prevent distraction of a straight line as it will be painted a sky scene exactly like the backdrop. I am hoping to add depth instead of "framing" the scene in the normal way. If it doesn't work out I'll just remove it and cut it straight and redo it the "normal" way but I think this is worth a try. Nothing ventured nothing gained. The valance also hides the lighting which I have also finished wiring for this area. Haven't turned it on yet because I don't have the fixtures installed. Yes, that's a outlet box that hasn't been wired . It comes off the wiring for the room behind the wall (workshop).

Sunday, October 31, 2010

A Tutorial

The Um6b has a set of dropped grab irons on the side of the unit just forward of the cooling air intake that serves as a ladder to the roof. They are pesky little dudes to make because they must be as nearly identical as possible. To be otherwise would make the oddballs stand out like a sore thumb. In addition they have to be mounted absolutely vertical and without variation, in line, one above the other. Eyeballing these babies is out of the question, at least with my eyesight ! The solution is a set of jigs and fixtures. They are simple to make, don't require much time or effort and are cheap.

The first is this simple aluminum angle 1/8" thick by 1"x1" x4" long with a .025 hole that is 17" from the notch filed in the end. This thing makes 18" long grab irons. Bend the wire stock over the notch as far as you can (I use .0225 brass) using your thumb and forefinger. It won't make 90 degrees so you'll have to adjust it with a pair of pliers. Use the inside of the aluminum angle as a guide but be careful as all extruded angle isn't necessarily 90 degrees either. When you buy it check, they won,t mind.

When you get it square, insert it in the hole and line up the unbent end over the notch. Bend it the same way you did the first bend.

Sorry about the blurry photo but you should be able to see enough to get the idea. The bend should come out about like the next picture.

Square this new bend up with the pliers using the aluminum angle as a reference. When that's done turn the wire sideways and check that it is not twisted. You should only be able to see one wire as in the next photo. This is critical. If you get things twisted the finished grab irons will never look right. Take the time to tweak them into shape.

In the photo below you'll see that I have made two notches in the edge of the aluminum angle. They are 18" apart. Just wide enough to hold the bent up grab iron, because we need to make another bend in both "legs" to get the drop in the finished piece. That bend has to be uniform in length.

As you can see I use another piece of angle to back up the grab iron while it is in the notches and then I use a flat needle file to hold it down and simply bend the legs over the edge of the angle. Voila! Consistant, uniform length bends. You have to make final adjustments to the bend angles with pliers as usual and all the bends must be parallel and square with each other or they won't set properly in the pre drilled holes. We're not finished yet, because those holes are just as important as the grab irons themselves and we need a couple more jigs to get this done.

This is the drill guide. It was made from .020 styrene and the cross member from .125 square styrene. The blade should have been .040. This was really too flexible but I made it work. Very carefull layout work pays dividends in the end. I centerpunch my holes with a pin using a magnifying glass and am very carefull to make sure I drill the holes as verically as I can. If you have a sensitive drill press, use it. These were done with a pin vise using a #74 drill. The thing is glued together with styrene adhesive. Be absolutely sure it is acurately positioned before glueing.

This is how it works. Notice the holes next to the guide below the grab iron. It works!! I clamped the guide in place with some small spring clamps. Probably a good idea. If you tried to hold it with your fingers it would most likely drift.

This is the last piece of fixture you need. Simply a piece of .060 styrene about 15" wide to space the grab irons a uniform distance from the surface while glueing. I used CYA from the inside of the car body. If things are a tiny bit out of whack you can bend the wire into shape at this stage. If it is a lot out of whack, pull the offending grab out and make a new one. When the adhesive sets, pull the spacer out,

and admire your work ! Still needed is the nut bolt washer detail at the top of each leg.

Does anybody really need this? I don't know but it was kinda' fun to do and so I may do some more as I progress with this model. I notice some strange effects with the photo's. The grab irons are perfectly straight as is the roof line of the engine. I don't do Photo Shop so don't know how to fix those things. My wife is good at it so I might have her take a shot at it when she gets some time. Might not be worth the effort. At any rate, the moral of the story is, jigs are simple and effective and mostly cost very little. Sometimes the effort to think of a way to do them is much more than the effort required to turn out the final product. Sometimes they are the only way.

The first is this simple aluminum angle 1/8" thick by 1"x1" x4" long with a .025 hole that is 17" from the notch filed in the end. This thing makes 18" long grab irons. Bend the wire stock over the notch as far as you can (I use .0225 brass) using your thumb and forefinger. It won't make 90 degrees so you'll have to adjust it with a pair of pliers. Use the inside of the aluminum angle as a guide but be careful as all extruded angle isn't necessarily 90 degrees either. When you buy it check, they won,t mind.

When you get it square, insert it in the hole and line up the unbent end over the notch. Bend it the same way you did the first bend.

Sorry about the blurry photo but you should be able to see enough to get the idea. The bend should come out about like the next picture.

Square this new bend up with the pliers using the aluminum angle as a reference. When that's done turn the wire sideways and check that it is not twisted. You should only be able to see one wire as in the next photo. This is critical. If you get things twisted the finished grab irons will never look right. Take the time to tweak them into shape.

In the photo below you'll see that I have made two notches in the edge of the aluminum angle. They are 18" apart. Just wide enough to hold the bent up grab iron, because we need to make another bend in both "legs" to get the drop in the finished piece. That bend has to be uniform in length.

As you can see I use another piece of angle to back up the grab iron while it is in the notches and then I use a flat needle file to hold it down and simply bend the legs over the edge of the angle. Voila! Consistant, uniform length bends. You have to make final adjustments to the bend angles with pliers as usual and all the bends must be parallel and square with each other or they won't set properly in the pre drilled holes. We're not finished yet, because those holes are just as important as the grab irons themselves and we need a couple more jigs to get this done.

This is the drill guide. It was made from .020 styrene and the cross member from .125 square styrene. The blade should have been .040. This was really too flexible but I made it work. Very carefull layout work pays dividends in the end. I centerpunch my holes with a pin using a magnifying glass and am very carefull to make sure I drill the holes as verically as I can. If you have a sensitive drill press, use it. These were done with a pin vise using a #74 drill. The thing is glued together with styrene adhesive. Be absolutely sure it is acurately positioned before glueing.

This is how it works. Notice the holes next to the guide below the grab iron. It works!! I clamped the guide in place with some small spring clamps. Probably a good idea. If you tried to hold it with your fingers it would most likely drift.

This is the last piece of fixture you need. Simply a piece of .060 styrene about 15" wide to space the grab irons a uniform distance from the surface while glueing. I used CYA from the inside of the car body. If things are a tiny bit out of whack you can bend the wire into shape at this stage. If it is a lot out of whack, pull the offending grab out and make a new one. When the adhesive sets, pull the spacer out,

and admire your work ! Still needed is the nut bolt washer detail at the top of each leg.

Does anybody really need this? I don't know but it was kinda' fun to do and so I may do some more as I progress with this model. I notice some strange effects with the photo's. The grab irons are perfectly straight as is the roof line of the engine. I don't do Photo Shop so don't know how to fix those things. My wife is good at it so I might have her take a shot at it when she gets some time. Might not be worth the effort. At any rate, the moral of the story is, jigs are simple and effective and mostly cost very little. Sometimes the effort to think of a way to do them is much more than the effort required to turn out the final product. Sometimes they are the only way.

Wednesday, October 27, 2010

Modifying the Modified

Or in other words Plan "C". You'll note that the car repair facilities have been moved to the yard. It will be served with dual gauge track . Again, "reach in" and depth allowed for scenery was at the tipping point so I felt it necessary to make this change. There is also a mistake in the left to right dimension of the room. It is actually 18" wider than on this drawing. Don't know how that happened but stuff does sometimes. It doesn't effect the overall design. Just imagine the yard tracks with a foot and a half more straight track stuck into the middle. When I am standing in the basement in the middle of this I can "see" the scenery much easier than on the drawing and I think this inability to translate the 2 dimension into three is why I keep having to change things. I also think it is why I look at layout design as sculpture more than an engineering or operational concept. And this is just the ten foot end of a nearly 40 foot long sculpture. Yikes!

When I am standing in the middle of this I see sight lines with trees and mountains and strucures and where water is or has been and where the trains must go. Where the lighting must be to avoid weird shadows and the structure to hold it all up. The backdrops are easier to visualize and I can see how other parts of the layout can help backdrop this section to help form a larger vista. I think that is going to turn out to be a key element in the overall impact of this project. The larger vista.

Subscribe to:

Comments (Atom)